Why Quality TMT Bars Matter More Than You Think

TMT (thermo-mechanically treated) rebars are the backbone of modern construction. They provide the necessary tensile strength and flexibility to structures, making them essential in residential, commercial, and industrial projects. Choosing the right one can be daunting with the market flooded with various TMT bar brands and grades. This guide walks you through key considerations to help you make an informed decision for your construction project.

Understanding What TMT Rebars Are

TMT rebars are steel bars that undergo a thermomechanical process combining heat treatment and rapid cooling. This results in a tough outer surface and a soft core, giving the bars a perfect balance of strength and ductility. TMT rebars are widely used in construction due to their resistance to corrosion, earthquake resilience, and longer life span.

Importance of Choosing the Right TMT Rebar

Selecting the right TMT bar isn't just about strength—it also affects your construction's durability, safety, and life. Using substandard or inappropriate rebars can lead to structural instability, increased maintenance, and potential disasters in extreme weather or seismic events.

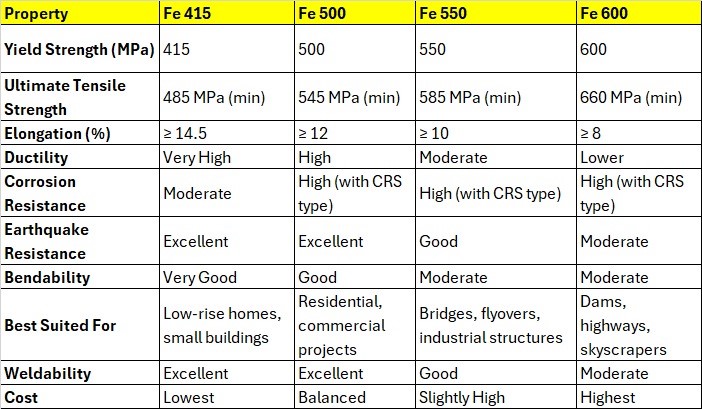

Know the Grades: Fe 415, Fe 500, Fe 550 & Fe 600

TMT rebars are categorized by their grade, which indicates their yield strength in megapascals (MPa).

- Fe 415: Best for small residential homes due to its excellent ductility.

- Fe 500: The most commonly used grade, suitable for most residential and commercial structures.

- Fe 550 & Fe 600: Used for heavy infrastructure like bridges, dams, and high-rise buildings where higher tensile strength is needed.

Check for ISI Certification and Quality Standards

Ensure that the TMT rebars you choose comply with BIS (Bureau of Indian Standards) and bear the ISI mark. This ensures that the bars meet Indian safety and quality benchmarks. Brands that adhere to IS 1786:2008 assure consistency in quality, dimensions, and chemical composition.

Consider Corrosion Resistance

For coastal or humid environments, corrosion-resistant TMT bars like CRS (Corrosion Resistant Steel) are a must. These bars have a special chemical composition with elements like copper, chromium, and phosphorus that protect against rusting, making them ideal for marine structures or areas with heavy rainfall.

Earthquake Resistance Matters

India falls under several seismic zones, making earthquake-resistant construction a necessity in many regions. TMT bars with high elongation properties can withstand seismic shocks without breaking. Look for TMT bars that comply with IS 13920, which deals with earthquake-resistant building design.

Ductility and Bendability

Construction often requires steel bars to be bent or shaped without cracking. Good TMT bars offer excellent bendability due to their soft inner core. This property allows them to absorb energy during earthquakes or wind pressure, maintaining the integrity of the structure.

Brand Reputation and Price

Don't just go for the cheapest option. Established brands offer better consistency, third-party testing, and warranty coverage. Some top brands in India include TATA Tiscon, JSW Neosteel, Shyam Steel, SAIL, and Kamdhenu. While the price might be higher, the long-term benefits far outweigh the cost difference.

Availability and Supply Chain

Ensure your chosen TMT brand has a reliable distribution network in your region. Consistent availability ensures there are no delays in procurement during different construction phases. Ask your dealer if they can ensure supply across the project timeline.

Look for Technological Advancements

Some TMT brands use advanced technologies such as Tempcore, German Thermex, or LRF (Ladle Refining Furnace) in the manufacturing process. These enhance strength, uniformity, and weldability. Choosing a technologically superior TMT bar ensures better performance over time.

Final Checklist Before Purchase

Before finalizing your TMT bar purchase, ask your supplier for:

- Grade and ISI Certification

- Chemical Test Report

- Ductility and Elongation values

- Brand authenticity

- Price per ton including GST and transportation

- Warranty or service support

Getting these details upfront saves you from poor-quality products and legal issues during compliance checks.

Conclusion

TMT rebars are one of the most crucial elements in ensuring the structural strength, safety, and longevity of a building. Making an informed choice by considering grade, quality, certifications, and environmental factors can prevent structural failures and save costs in the long run. Collaborate with trusted dealers and construction experts to get the best results for your project.